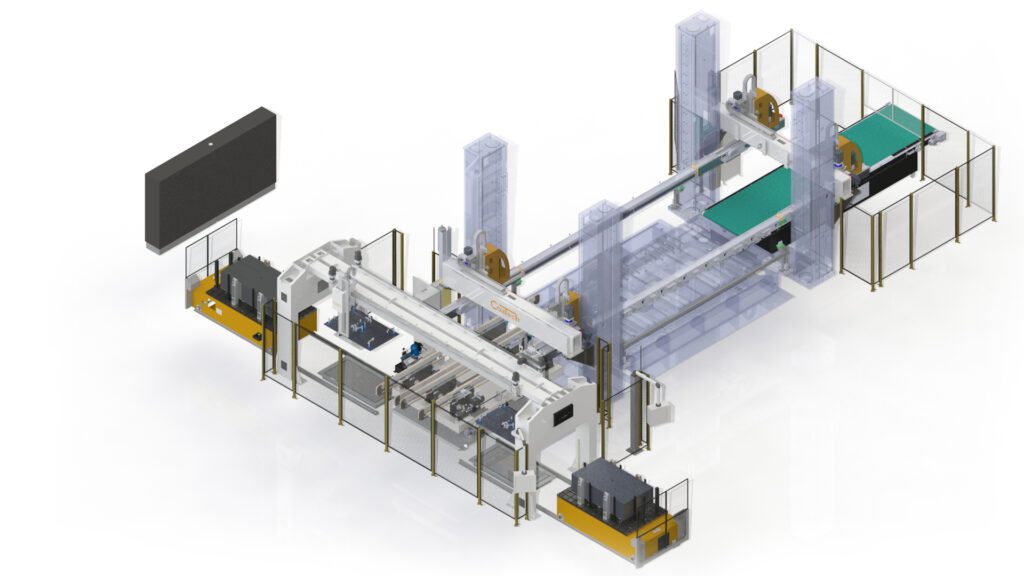

Transfer Systems and Automation Solutions

In industrial manufacturing, transfer systems play a crucial role in moving products efficiently, safely, and accurately along production lines. As of 2025, trends such as smart manufacturing, automation, and flexible line design have made transfer systems more critical than ever.

What Are Transfer Systems?

Transfer systems are mechanical and automated solutions designed to transport parts or products in a specific sequence along a production line. They are widely used in:

-

Assembly lines

-

Packaging lines

-

Painting and welding lines

-

Logistics and warehouse automation

These systems ensure smooth and efficient product flow while maintaining high productivity.

The Importance of Transfer Systems in 2025

In 2025, industrial production emphasizes efficiency, flexibility, and digitalization. Transfer systems lie at the heart of these trends:

-

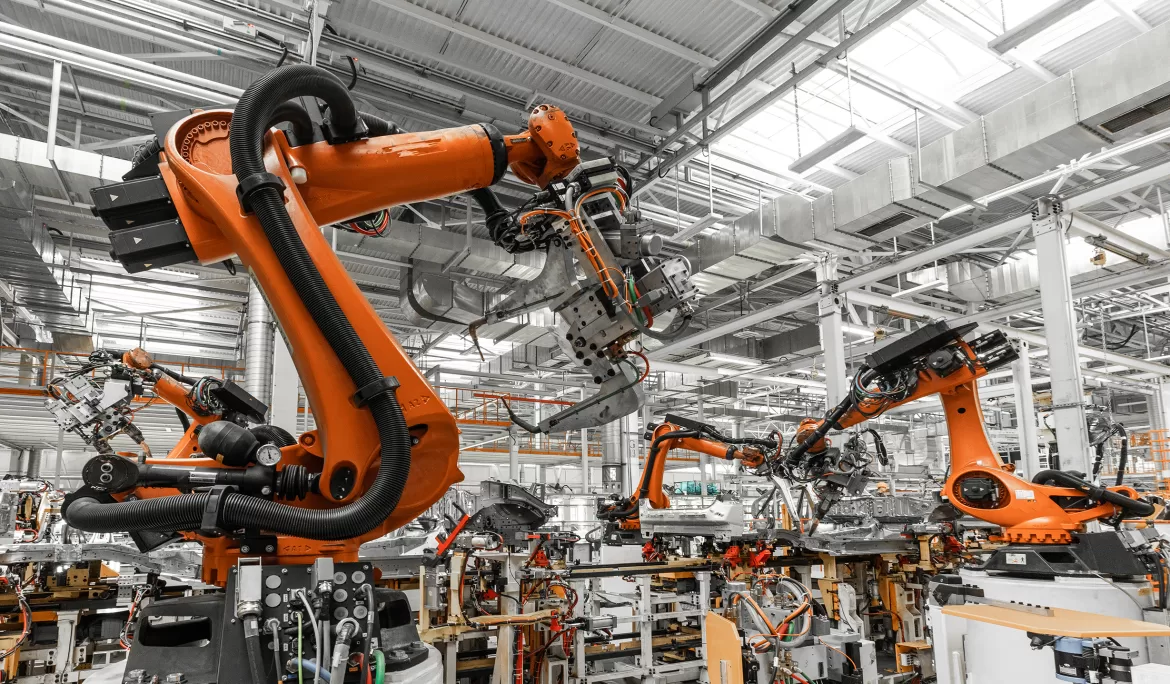

Automation and Robotics Integration: Modern transfer systems are integrated with robotic arms and smart conveyors, reducing human intervention and increasing production speed.

-

Energy Efficiency: Next-generation motors and energy recovery technologies help minimize energy consumption.

-

Digital Traceability: IoT sensors allow real-time tracking of products along the production line.

-

Flexible Manufacturing: Modular designs make it easy to adapt transfer lines for different products and production volumes.

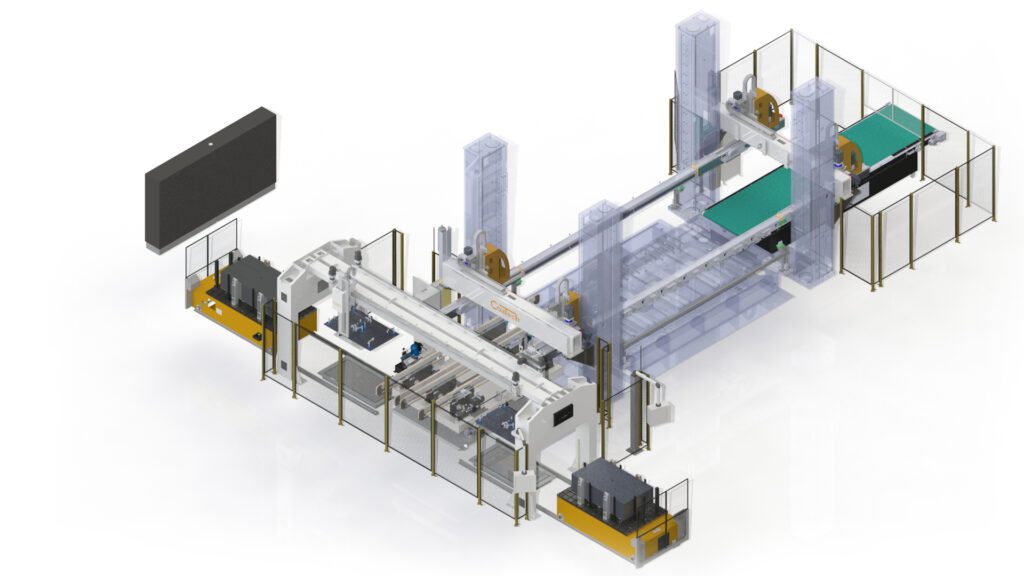

Designing Transfer Systems

Key priorities in designing transfer systems include:

-

Speed and Flow Optimization: Ensuring products move at the right pace and sequence.

-

Material Compatibility: Designing systems to handle different product weights, sizes, and sensitivities.

-

Durability and Maintenance: Components must be long-lasting and easy to maintain.

-

Safety Standards: Design must ensure worker safety and operational reliability.

Modern design processes often use 3D modeling, simulation, and digital twin technologies to test line performance before physical implementation.

Production and Installation Processes

-

Component Manufacturing and Assembly: Transfer system parts are manufactured with high precision and assembled.

-

Testing and Calibration: Before installation, systems are tested for speed, accuracy, and reliability.

-

Installation and Integration: Systems are installed on-site and integrated with other automation equipment.

-

Commissioning and Monitoring: Once operational, performance and energy consumption are continuously monitored.

2025 Trends and Future Outlook

-

Smart Factories: Transfer systems leverage AI and data analytics to optimize production lines.

-

Sustainable Manufacturing: Environmentally friendly systems reduce energy and material usage.

-

Modular and Adaptive Lines: Production lines can be quickly reconfigured to meet changing product demands.

Conclusion

In 2025, transfer systems in industrial production lines are no longer just conveyors for products—they are key enablers of efficiency, energy savings, and digital integration. Manufacturers investing in these systems gain cost advantages while building competitive, future-ready production environments.

Son Haberler

-

03 Sep, 2025

03 Sep, 2025Transfer Systems and Automation Solutions

-

03 Sep, 2025

03 Sep, 2025BIW Project Design and Production Processes

-

03 Sep, 2025

03 Sep, 2025Custom Machine Designs and Industrial Automation