Custom Machine Designs and Industrial Automation

Industrial production and automation continue to evolve rapidly in 2025 at the intersection of technology and innovation. Companies aim not only to increase production capacity but also to optimize processes, reduce costs, improve quality, and achieve sustainable solutions. In this context, custom machine design and industrial automation play a critical role.

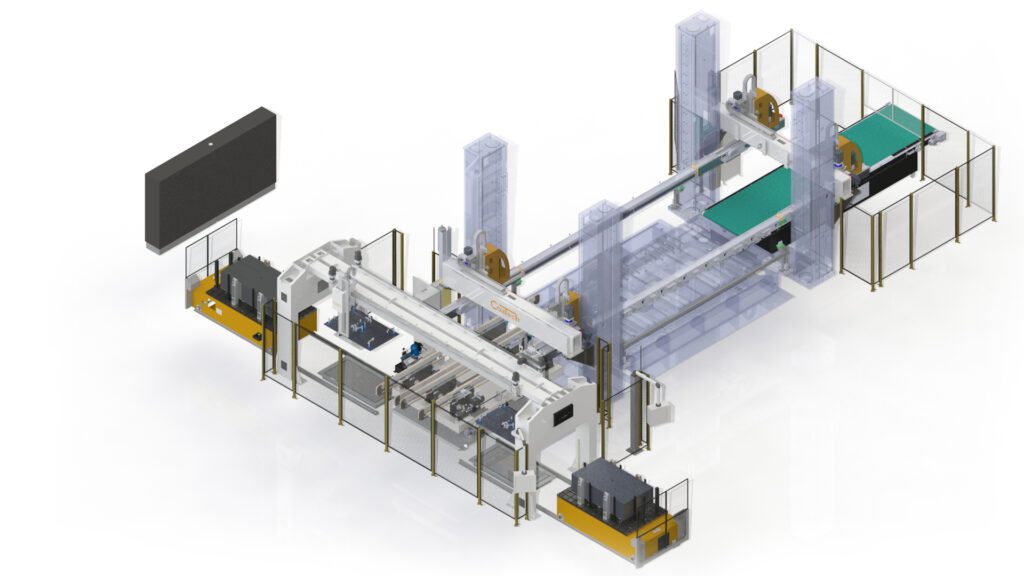

Custom Machine Design: Tailored Solutions for Businesses

Every production line has unique requirements. In 2025, companies are increasingly turning to custom machine designsas an alternative to standard machines. These machines provide solutions for sectors such as:

-

Press assembly and ultrasonic welding in the automotive industry

-

Riveting and assembly operations in white goods production

-

High-precision feeding and processing machines in metal and plastic manufacturing

With custom machine designs, businesses can operate production lines with maximum efficiency and flexibility, minimize downtime, and maintain the highest quality standards.

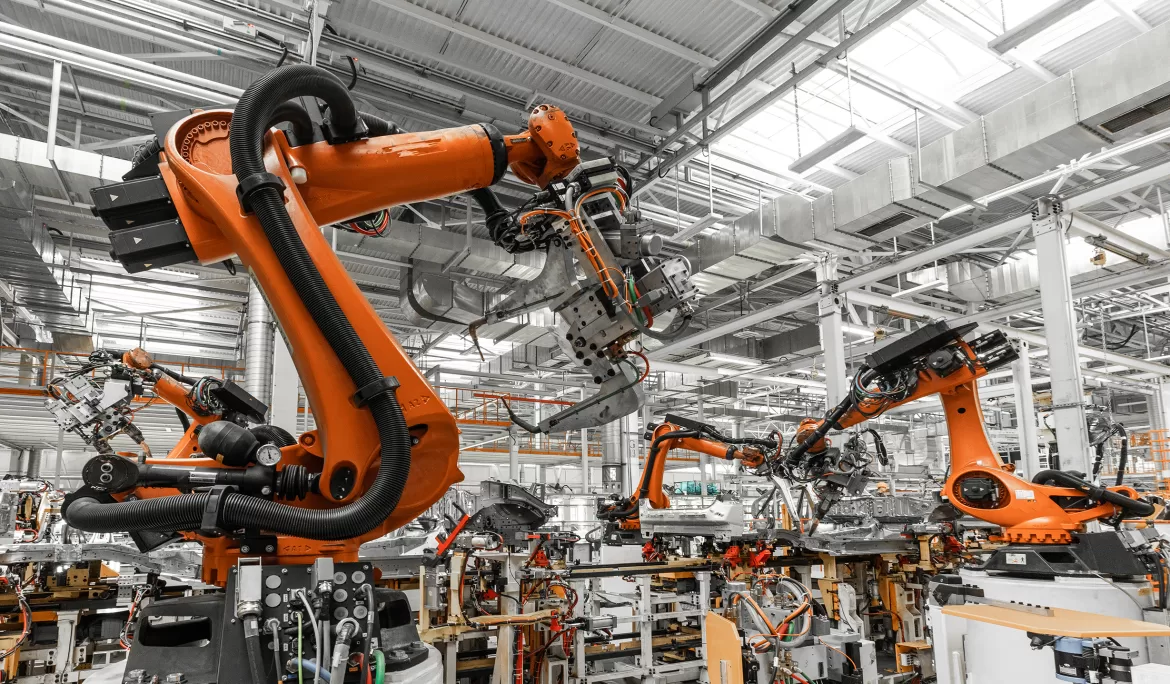

Industrial Automation: Efficiency and Digitalization in Production

By 2025, industrial automation goes beyond robotic lines and machine controls. Companies leverage process simulation, data analytics, IoT-based monitoring, and AI-supported optimization to make their production processes smarter.

Industrial automation systems provide benefits in areas such as:

-

Offline programming and cycle optimization for robotic production lines

-

Automated transfer and material handling systems

-

Smart storage and AS/RS solutions

-

Precise robotic applications for sealer and paint shop lines

These solutions save time and reduce costs while increasing productivity and operational reliability.

Key Trends in 2025

-

Sustainable Manufacturing: Energy-efficient machines and automation solutions take priority.

-

Flexible Production Lines: Modular and scalable systems capable of adapting quickly to changing market demands.

-

Digital Twin and Simulation: Production processes are tested and optimized virtually using simulation and digital twin technologies.

-

Integrated Data Analytics: Real-time production data enables faster, data-driven decision-making.

Conclusion

In 2025, custom machine design and industrial automation not only enhance production line performance but also directly impact a company’s competitiveness, sustainability, and quality standards. Businesses are integrating technology and innovation into production processes to build the manufacturing lines of the future today.

Based in Kocaeli, Prosimtech continues to provide reliable, innovative, and efficient solutions in custom machine design and industrial automation, helping businesses optimize their production processes and stay ahead in a rapidly evolving industry.

Son Haberler

-

03 Sep, 2025

03 Sep, 2025Transfer Systems and Automation Solutions

-

03 Sep, 2025

03 Sep, 2025BIW Project Design and Production Processes

-

03 Sep, 2025

03 Sep, 2025Custom Machine Designs and Industrial Automation