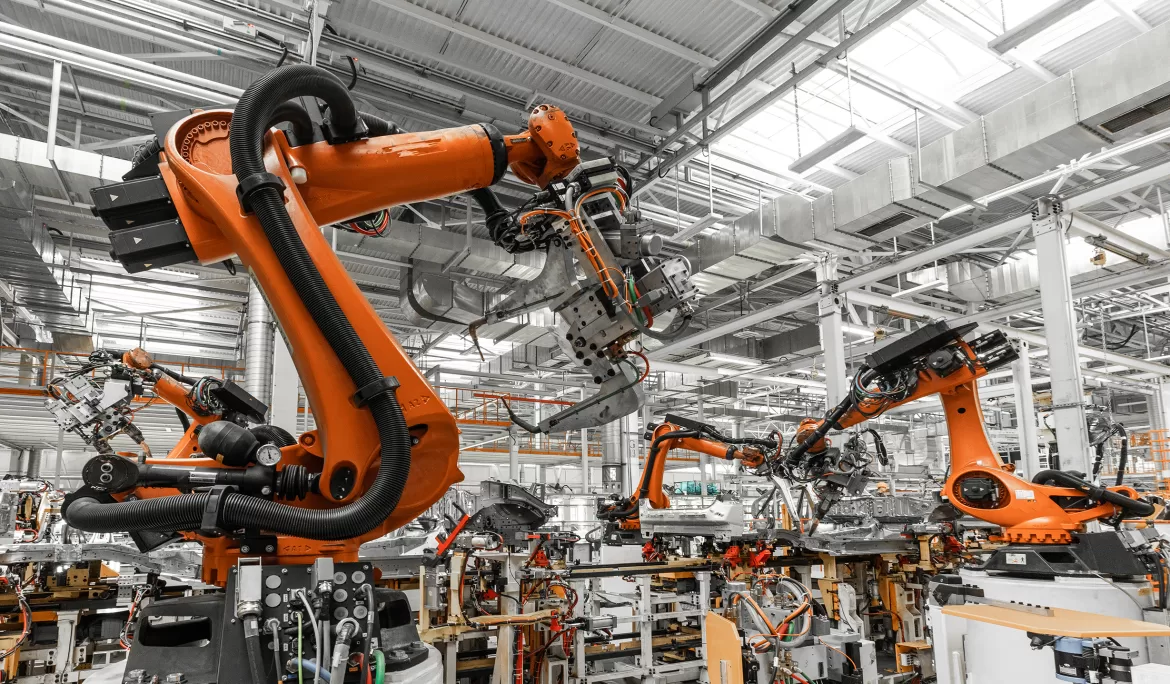

BIW Project Design and Production Processes

In the automotive industry, BIW (Body in White) project design and production processes cover critical stages from planning the vehicle’s body structure to its assembly. These processes are essential for vehicle safety, durability, and production efficiency.

What is BIW?

Body in White (BIW) refers to the vehicle body composed of welded steel or aluminum before painting and final assembly. During the BIW stage, the following steps are completed:

-

Designing body components

-

Determining welding and joining points

-

Performing simulations and analyses for production

This stage is one of the most critical structural phases before the vehicle reaches final assembly.

BIW Project Design

BIW design forms the foundation of the manufacturing process. Key activities in the design phase include:

-

CAD Modeling: Body components are designed using 3D CAD software.

-

Simulation Analyses: Durability, crash safety, and welding points are analyzed.

-

Material Selection: Steel, aluminum, or composite materials are selected.

-

Prototype Production: Prototypes are manufactured for on-site testing of the design.

This phase reduces costs and ensures high-quality production.

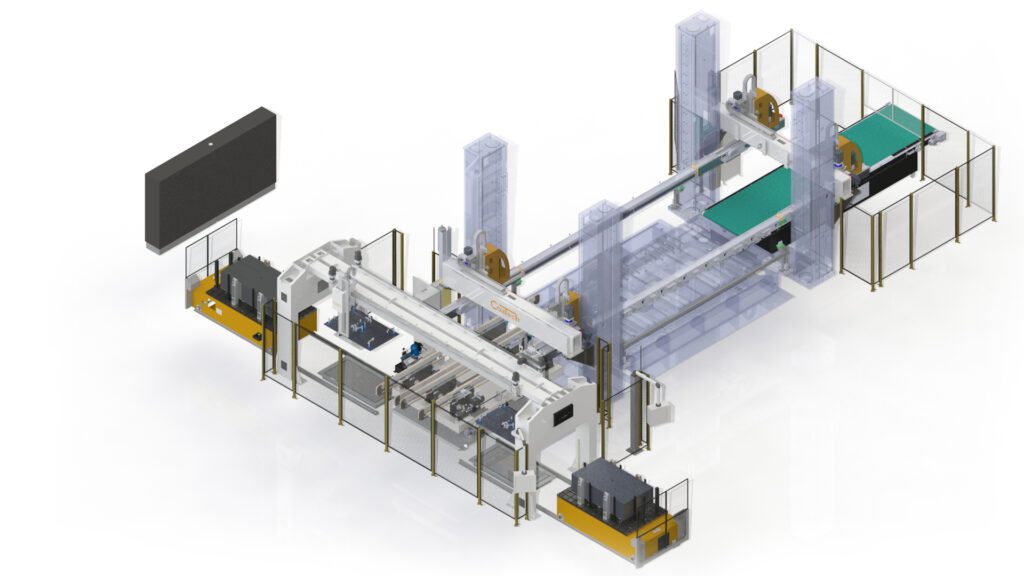

BIW Production Processes

BIW production includes critical processes following the design phase:

-

Cutting and Forming

Body panels are cut using laser or plasma machines and shaped with presses, ensuring precision and assembly compatibility. -

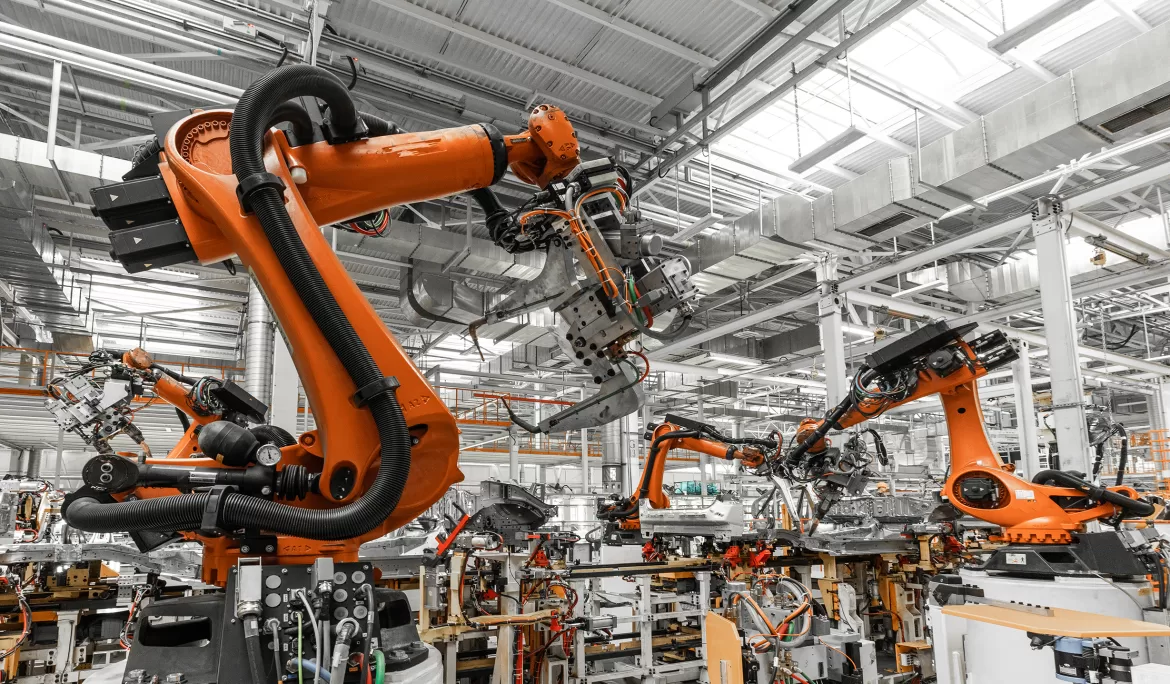

Welding and Assembly

Components are joined using robotic welding systems, including spot welding and MIG/MAG welding. This step is crucial for vehicle strength and safety. -

Simulation and Quality Control

During production, crash tests, rigidity analyses, and tolerance inspections are conducted. Early detection of defects reduces costs and production time. -

Pre-Painting and Assembly Preparation

After welding and assembly, the BIW is prepared for painting and final assembly. Surface cleaning, primer application, and corrosion prevention measures are applied.

Efficiency and Digitalization in BIW Processes

Digital transformation is increasingly important in BIW processes:

-

CAD/CAE simulations enable early detection of errors

-

Robotic automation increases speed and precision in welding and assembly

-

Data analytics and IoT monitor production performance

These solutions shorten production times while reducing costs and improving quality.

Son Haberler

-

03 Sep, 2025

03 Sep, 2025Transfer Systems and Automation Solutions

-

03 Sep, 2025

03 Sep, 2025BIW Project Design and Production Processes

-

03 Sep, 2025

03 Sep, 2025Custom Machine Designs and Industrial Automation